Precision Engineered Excellence

CNC milling

Milling is a versatile machining method used in various industries to produce parts with precise dimensions, smooth surfaces, and complex geometries. It is commonly used in metalworking but can also be applied to other materials such as plastics and composites. Milling is a machining process that involves removing material from a workpiece using a rotating cutting tool.

Electrical

Discharge

At Fabrik, we provide two advanced types of Electrical Discharge Machining (EDM) processes designed to tackle the most challenging manufacturing requirements. Our EDM capabilities excel in cutting deep pockets, intricate features like gears, and keyway holes, all while preserving the integrity of delicate structures.

CNC

Turning

When it comes to cylindrical parts like pins, shafts, and spacers, as well as components with rotational symmetry, turning them on a lathe is often the most straightforward and cost-effective method. Unlike a mill, a lathe operates by securing a cylindrical stock, commonly known as a rod, into a rotating chuck jaw on the machine.

Gear

hobbin

Hobbing is a versatile machining process used to cut gear features on both metal and non-metal parts. By employing a cutting tool called a hob, gear teeth (or splines) are incrementally formed into a cylindrical workpiece. Hobbing enables the creation of a wide range of gear shapes and sizes, including spur gears, worm gears, and bevel gears.

Unveiling the Process of CNC-Machined Parts Production

Quoting process

Express quotes – often on the same day Two-stage technical feasibility check Flexible offer optimization regarding price or delivery time

Order placement

More than 2000 specialized manufacturing partners AI-supported selection of the optimal manufacturer Fabrik is the sole contractual and contact partner

Manufacturing

Broadest manufacturing range in the market Unlimited production capacity ISO 9001 certified quality management

QUALITY CONTROL

By any modern statistical measure, Fabrikmeets or exceeds the quality standards of the world’s most demanding industries.

Shipment

Experience consistently short delivery times with our USA-wide express shipping service. Enjoy the convenience of swift deliveries while knowing that our operations are 100% climate neutral, contributing to a sustainable future for all.

Order tracking

Receive real-time production status updates for your orders at your convenience—access exclusive part photos and comprehensive inspection data even before your items are delivered.

- Eco Innovation

Customer empowerment in a future-focused world

Elevate your applications with Fabrik Process Technology Section. Our expert teams offer cutting-edge solutions, computational modeling, and technical support for a sustainable future across all areas of the business. Join us in driving excellence and innovation.

At Fabrik’s Product Technology Section, our engineers and professionals utilize an extensive range of advanced and sophisticated resources. From cutting-edge testing to modeling and failure analysis, we pave the way for the next generation of steels in virtually every application. In our state-of-the-art laboratories and facilities, the future takes shape.

- Products

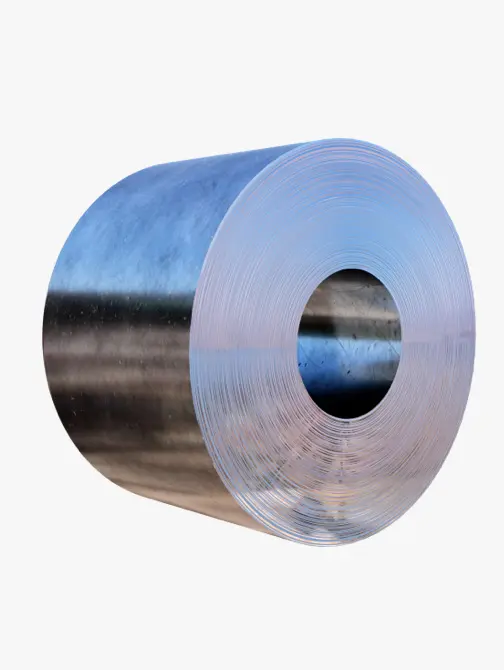

Sustainable steel for a stronger tomorrow

- Careers

Pioneering a New Era of Steelworking Excellence

Are you ready for a meaningful career that rewards you for your contributions? Join us, and together, we will challenge the status quo, exceed expectations, and create a future for steelworking that is filled with endless possibilities.

Investor events

Unlocking value through investor events: building relationships, sharing insights, and maximizing opportunities.

Investors

Forging lasting connections with investors: cultivating trust, delivering results, and driving sustainable growth.

Stock information

20 minutes minimum delay | June 9, 2023 4:00 PM EST